Home » Activated carbon recycling » Activated carbon reactivation

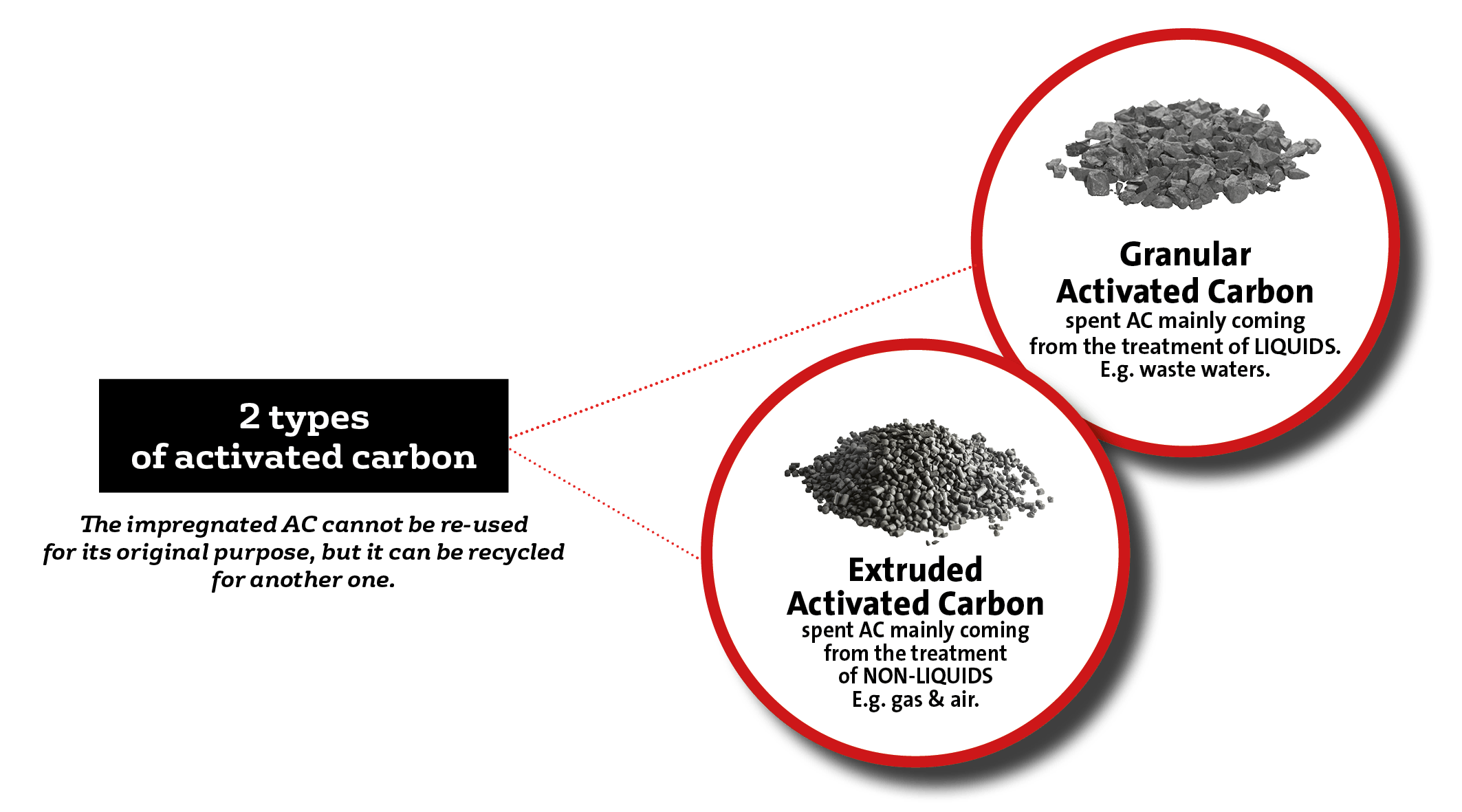

Activated carbon is used to purify gases and air as well as waste water. Following its use, it becomes saturated with pollutants, becoming waste which can however be recycled. BATREC treats used activated carbon in order to give it a second life.

A unique process...

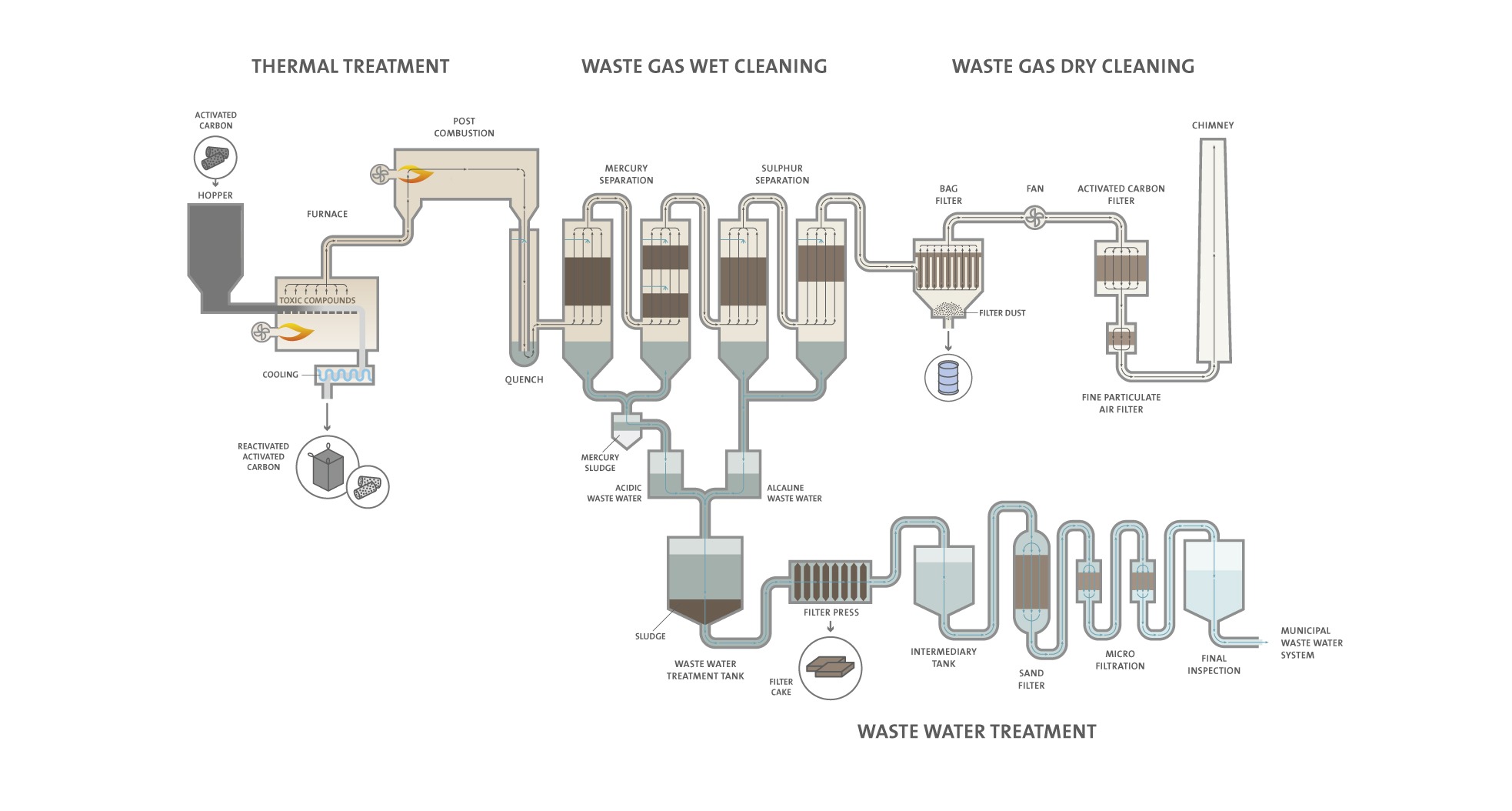

During use, activated carbon captures pollutants (such as VOCs, sulfur, chlorine, mercury, etc.). Once saturated, a high temperature treatment of up to 850°C allows it to have a second life. The pollutants are first destroyed in a post combustion chamber at high temperature. The off-gas is then treated via several scrubbers and filters ensuring environmentally safe emmisions.

... and cost effective

This alternative to landfilling waste and buying a new product has a positive impact, both economic and environmental. Overall, the cost of reactivation will always be cheaper than disposing of spent activated carbon and buying new carbon to refill a filter.

Focus on the process

Here is the flowsheet of our reactivation unit including the thermal treatment step, the wet off-gas treatment process and finally the dry off-gas treatment step.